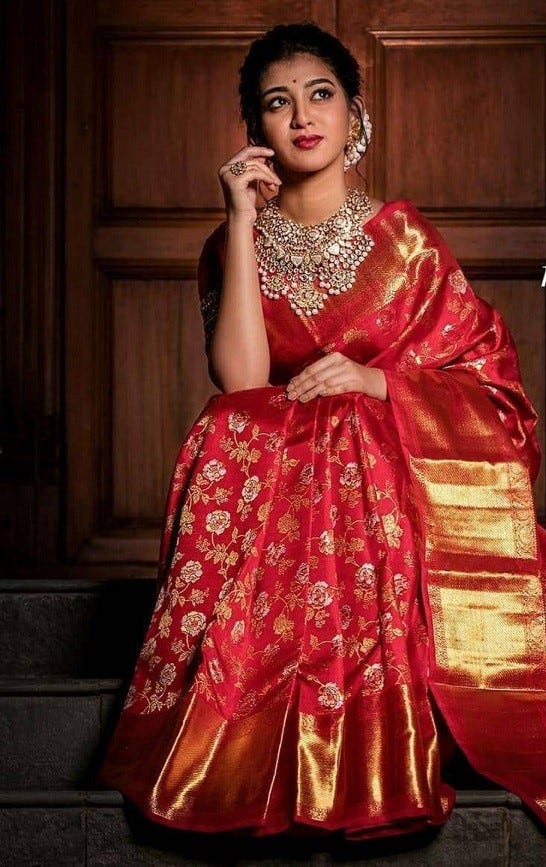

The Handloom Silk Sarees: Exclusive Craft With Intricate Designs , Motifs and Colors

Handwoven silk sarees are essential keepsake of Indian cultural wardrobe

Handloom Silk Sarees are made from Silk threads by processing silk, dyeing, warping and sizing. Attaching the warp, weft and winding and weaving done by local weavers and silk specialists and design creators in waving villages. This is especially true in North India in Benaras or Varanasi and South India Tamil Nadu and Karnataka states. The Handloom Silk Sarees: Exclusive Craft With Intricate Designs, Motifs and Colors, are favorite of most Indian Women worldwide.

Silk Fiber

Silk which is a natural protein fiber is obtained from cocoons of larvae of Mulberry silkworm Bombyx mori, and other Bombyx speciesreared in sericulture (silk farming) for commercial production of silk. The protein fiber is mainly fibroin and sericin protein, which is produced by larvae to form cocoon.

Silk threads are also obtained from lotus flower stems. This is most ecofriendly creation of silk as there is no chemical and harmful toxins involvement during process of creation. Fabric created from this fiber is light and breathable.

Silk is expensive because of limited availability and costly manual, labor intensive production process. On a rough estimate 7Kg (or 5000) of cocoons produce 1Kg silk. Which is then processed to create silk thread, sold commercially in spools, for making silk fabric.

History of Silk

Silk fabric was invented in Ancient China in 27th Century BC by Empress Xi-Ling -Shi of Shang Dynasty. Since then it has played a major role in Chinese economy and culture and spread of business of silk in European and Asian subcontinents.

Silk Road was link between China and West for trade of goods as tea, spices, paper, porcelain, bronze including “Silk”. It was network of trade routes connecting East and West. India and China are now world’s largest producers of silk. Combined silk production is more than 60% of global silk production from these two.

Sericulture

Silkworm farming or raising silkworms to obtain silk is more than 5000 years old process. The whole process of silk making involves three major steps

Moriculture: Growing Mulberry trees for silk larvae feeding. Cultivation of plants from seeds, root grafting, stem grafting is done in the field. Mulberry leaves are hand picked from branches and top shoots and spread on beds or trays for feeding larvae.

Sericulture: Raising silkworms for production of silk cocoons. Farmers raise silkworms in racks in buildings. Place silkworm beds or trays on racks, where the silkworms will feed on mulberry leaves and grow. Some farmers prefer aluminum boxes with controlled conditions.

Silk moth (Bombyx mori) eggs transform to silkworms/caterpillar/larvae, wrap them selves in silk thread produced from their salivary glands in the process of growing and transform to pupae in cocoons, which are then processed at fixed time (before worms make hole in cocoon) by boiling and silk is extracted.

Silk Reeling: Obtaining silk from cocoons and reeling the filament produced. Finally the silk filament obtained are woven together to form silk thread. One thread contains around 50 silk filaments. These silk thread are plied together to make yarn and sold on spools commercially.

The domestic silkmoth Bombyx mori and other silk moths (Muga, Eri, Tasar for “wild silk”) caterpillars are cultivated for silk production.

The pigment Xanthophyll present in layer of Sericin protein imparts color to silk. Following are type of silk produced and color of fiber:

Type of Silk and Color of Fiber:

- Mulberry Silk — Yellow/Green color

- Eri Silk — Creamy- White/Brick- Red color

- Tasar Silk — Copper-Brown color

- Muga Silk — Golden color.

Silk producing states in India

Following are silk producing states in India:

- Karnataka

- Andhra Pradesh

- Assam

- West Bengal

- Tamil Nadu

- Jharkhand

- Meghalaya

- Nagaland

- Manipur

- Chattisgarh

- Maharashtra

- Uttar Pradesh

- Telangana

Silk Types in Sarees

Different famous silk saree types are available in beautiful designs and colors, a perfect Indian clothing for women of all ages and for all occasions. As solids, zari borders, checks and stripes, intricate brocade embroidery with zari and metal-Silver and Gold work, beautiful floral and scenic motifs as bel-buttis, Zaal, jangala, Shikargah, butidar, tanchoi, cutwork, tissue, mythological scenes and tales created by handloom artisans.

They are available in all combinations of vibrant and pastel colors:

- Kanchipuram Silk or Kanjivaram Silk

- Banarasi Silk

- Mysore Silk

- Chanderi Silk

- Chettinad Silk

- Konrad Silk

- Patola Silk

- Ikat Silk

- Baluchri Silk

- Art Silk

Banarasi Sarees

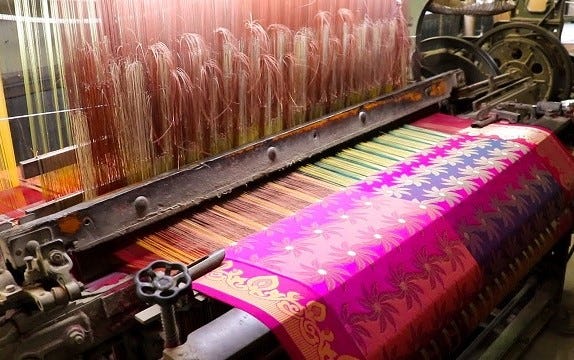

Banarasi sarees are traditionally woven on Jacquard pit loom with longitudinal warp (Tana) silk thread and latitudinal weft(Bana) silk thread. Shuttle of weft moves on tightly held warp thread on loom and in the process threads are interwoven.

Jacquard cards attached to jacquard machine and silk threads are pulled according to design and motif and hence the design is woven on saree by specialist weavers, who are working on the craft for generations.

The cost of this expensive creation is well understood if one knows the efforts and hardwork involved in this brilliant handloom handicraft.

Normal time to weave one Banarasi saree is 15–30 days depending on the floral or zaal motif and intricacy and complexity of work, that too involve 3 weavers at a time. Some creations may take upto six months for completion.

Banarasi silk sarees are essential attire for Indian brides and hallmark of bridal wear sarees.

These Banarasi silk sarees are epitome of elegance, grace and beauty and fashion at the same time.

The grand brocade intricate designs and zari work in Gold and Silver may never go out of style for generations to come.